About Me

I am a recent graduate in Mechanical Engineering from Louisiana Tech University. I graduated with a Bachelor of Science and am currently pursuing a full-time mechanical engineering position.

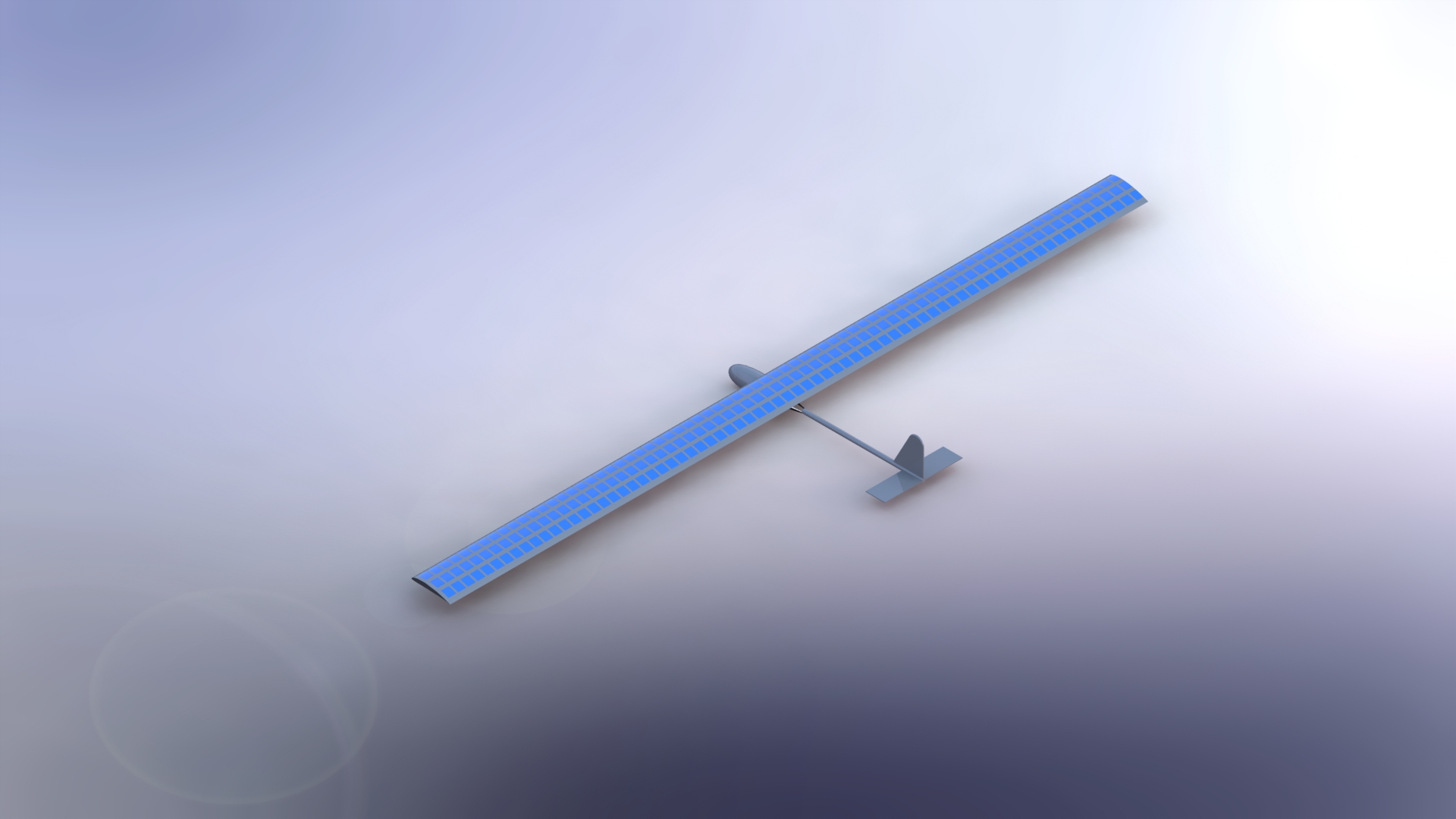

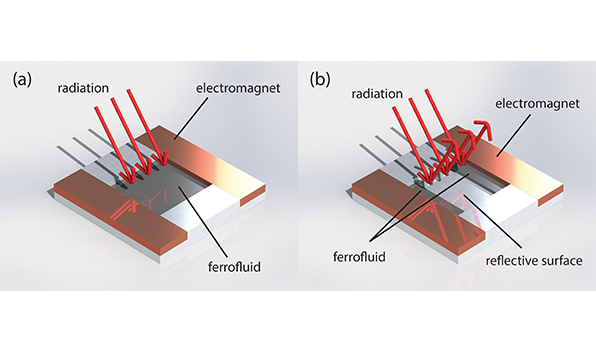

Right now I am hard at work on two exciting projects in the research and development area. I am currently building a solar-powered UAV designed to break the world record for continuous flight time in its class. Additionally, I am conducting testing on my original idea of a variable emissivity surface designed to allow for the precise control of the temperature of satellite through positional control of ferrofluid using electromagnets.

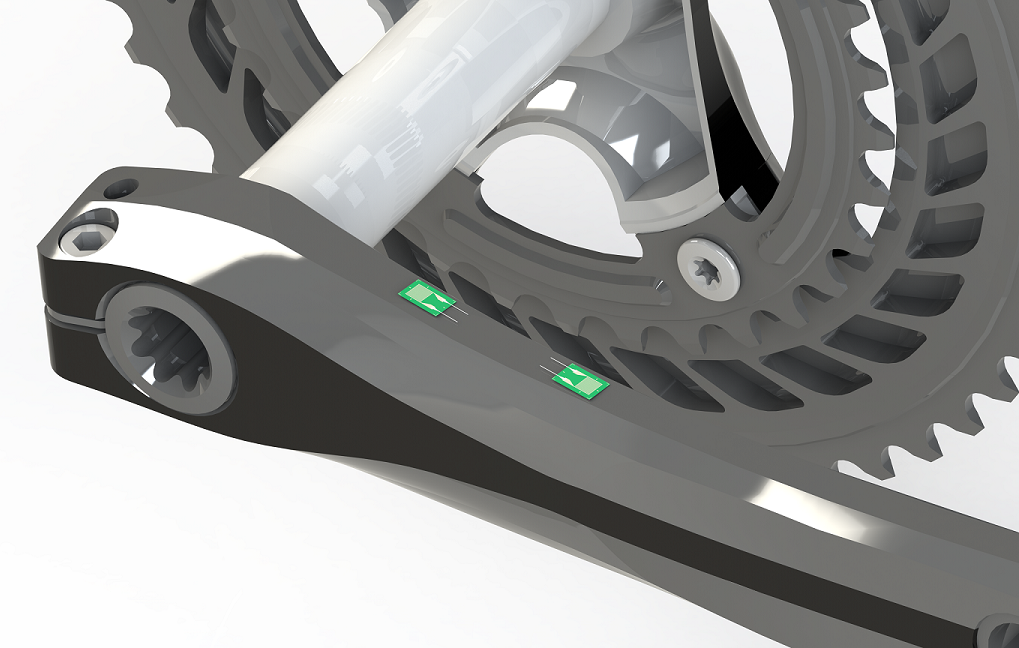

Outside of research, I have been building a cycling power meter at 1/10th the cost of a typical product with identical functionality. My interest in both design projects and cycling led me to pursue this project. I've been riding for most of my life and over the past year have begun focused training. I currently race both road and mountain bike races and have several lined up on my calendar for the upcoming months.

Below you will find information about my education, past experience, and both personal and academic projects I have taken on. These projects represent the quality of my work and my passion for the field of engineering.

Projects

Education

Louisiana Tech University

B.S. Mechanical Engineering

2015-2019Current GPA: 3.42/4.00

Coursework

Advanced Fluid Dynamics

Thermodynamics & Thermal Design

Computer Aided Modeling

Circuits

Dynamics

Statics I-IV

Internal Combustion Engines

Engineering Problem Solving I, II, III

Skills

Professional

Technical Report Authoring

Data Analytics

Team Leadership

Long-Term Project Planning

CAD & Simulation

Solidworks

AutoCAD

Revit

Inventor

ANSYS

Creo

Programming

Python

MATLAB

Mathcad

R

C

C++

Work

Intern - LG Electronics USA, Inc. (Air Conditioning Technologies)

I worked with a team of process engineers to redesign LG’s design workflow and efficiency, especially with the partner design group in South Korea. I modeled air conditioning solutions for buildings using AutoCAD Revit and LATS and performed research on competitors’ products to increase market potential.

Undergraduate Research Assistant - Institute for Micromanufacturing (IfM), Louisiana Tech University

In this position as research assistant I research the thermal conductivity of cellulose nanocrystals. This is accomplished utilizing a process of data collection to determine efficiency of cellulose nanocrystals for applications in sustainable electronics. In order to do this, I operate testing of samples in a clean, vacuum environment to minimize experimental error over a very large set of samples.

Intern - Singleton’s Drilling LLC

In this internship, I fabricated and assisted in the design of a portable water well drilling rig. Over the course of the summer I created a system of improvements for the rig after analysis of rig workflow. I also drilled and maintained water wells, serving the entirety of St. Tammany Parish, installed and serviced pumps, tanks, and water filters. As a result of my work, I became proficient in metal fitting and gained a working knowledge of stick welding.

Camp Counselor - Camp Chosatonga

In this position as camp counselor, I was personally responsible for the well-being and health of over 100 campers over the course of the summer. I worked as a climbing guide and I spent my summer helping the campers have a great experience in the North Carolina wilderness. I worked with over 60 other counselors to care for these campers, manage camp activities, and make sure everybody was in good health and remained safe.

Publications

Reaz A. Chowdhury, Amit Rai, Evan Glynn, Patrick Morgan, Arden L. Moore, Jeffrey P. Youngblood, Superior, processing-dependent thermal conductivity of cellulose Nanocrystal-Poly(vinyl alcohol) composite films,

Polymer, Volume 164, 2019, Pages 17-25, ISSN 0032-3861

Abstract: The in-plane thermal conductivity of cellulose nanocrystal (CNC) – poly(vinyl alcohol) (PVA) composite films containing different PVA molecular weights, CNC loadings and varying order parameters (S) were investigated as an eco-friendly, renewable and sustainable alternative to commonly used petroleum-based polymeric materials for potential application in thermal management of flexible electronics. Isotropic CNC-PVA bulk films with 10–50 wt% PVA solid loading showed significant improvement in thermal conductivity compared to either one component system. Further, anisotropic composite films exhibited in-plane thermal conductivity as high as ∼3.45 W m−1 K−1 in the chain direction, which is higher than most polymeric materials used as substrates for flexible electronics. Such an improvement can be attributed to the inclusion of PVA as well as to a high degree of CNC orientation. Further, a theoretical model was used to study the effect of CNC arrangement (both isotropic and anisotropic configuration) and interfacial thermal resistance on the in-plane thermal conductivity of the CNC-PVA composite films. In order to demonstrate an application for flexible electronics, thermal images of a concentrated heat source on both neat PVA and CNC-PVA composite films were taken that showed the temperature of the resulting hot spot was lower for the composite films at the same power dissipation.